Kennedy Galvanizing - Protecting Metal With Care

When you need metal items looked after with a protective coating, a name that often comes up for its steady work and quick service is Kennedy Galvanizing. This place has been in the business of keeping metal safe from the elements for quite a while, starting its operations back on March 4th, 1988. They are, in a way, a go-to spot for many looking to get their metal pieces treated with a special kind of care.

They have a particular knack for what is called "spin" galvanizing, which is a method used for smaller parts, making sure each piece gets a thorough covering. But they also handle bigger items, structural pieces that can reach quite a length, up to twenty-nine feet, which is really something. What truly sets Kennedy Galvanizing apart, though, is their ability to get things done quickly, especially when you are in a hurry. They pride themselves on handling expedited requests and typically offer what you might call an extraordinary speed of service compared to others who do similar work, which is pretty helpful, you know?

You can find Kennedy Galvanizing situated in Hanceville, Alabama, at 301 Industrial Boulevard. This location serves as a central point for their operations, allowing them to provide their specialized services to a range of clients. They have been providing good service and hot-dipped galvanizing for over a quarter of a century, making them a well-established presence in the area, and that, is that, a lot of experience.

Table of Contents

- What Does Kennedy Galvanizing Do, Exactly?

- How Long Has Kennedy Galvanizing Been Around?

- Where Can You Find Kennedy Galvanizing?

- What Makes Kennedy Galvanizing Different?

- Who Helps Make Things Happen at Kennedy Galvanizing?

- A Closer Look at What Kennedy Galvanizing Offers

- Ensuring Good Work at Kennedy Galvanizing

- Connecting with Kennedy Galvanizing

What Does Kennedy Galvanizing Do, Exactly?

The Heart of Kennedy Galvanizing's Work

At its core, Kennedy Galvanizing works as a job shop that applies a protective zinc coating to metal. This process, known as hot-dip galvanizing, is a way to keep metal from wearing down or rusting over time. It is a very practical method for making metal items last much longer, especially when they are exposed to different weather conditions or other harsh environments. They take raw metal pieces and treat them, giving them a shield against things that would otherwise cause them to break down, which is pretty useful, actually.

Their particular skill lies in what they call "spin" galvanizing. This technique is often used for smaller metal parts, like fasteners, bolts, or other tiny pieces that need a consistent, even coat of zinc. With spin galvanizing, these smaller items are dipped into the molten zinc and then spun at high speeds. This spinning action helps to remove any excess zinc, ensuring a smooth, uniform covering on each small component. It is a precise way of doing things, making sure every little bit is protected, and that is a key part of what Kennedy Galvanizing does.

Beyond the smaller items, Kennedy Galvanizing also works with much larger structural pieces. They are equipped to handle items that can measure up to twenty-nine feet in length. This means they can take on bigger jobs, like beams or other parts used in building projects, providing them with the same durable, rust-resistant coating. The ability to manage both small, intricate pieces through spin galvanizing and large, long structural components shows a breadth of capability in their operations. It is almost like they can handle a wide range of needs, from the very small to the quite big, so they are quite versatile.

How Long Has Kennedy Galvanizing Been Around?

A Look at Kennedy Galvanizing's Past

Kennedy Galvanizing has a history that goes back quite a bit. They first opened their doors and began their work on March 4th, 1988. That is a solid number of years in the business, showing a consistent presence and dedication to their craft. Over the years, they have built up a good amount of experience, which helps them understand the different needs of their clients and how to best serve them. It is a long track record, meaning they have seen a lot and learned a lot along the way, you know?

The company was formally set up as an Alabama domestic corporation a little later, on May 19, 1988. This official step solidified their standing as a business entity within the state. The registered agent on file for the company is listed as Davis, Dollie L., with the business address at 301 Industrial Boulevard SE, Hanceville, AL 35077. These details show the formal structure and legal foundation upon which Kennedy Galvanizing has operated for many years. It is all very proper and established, so they are quite legitimate.

Having been in business for over twenty-five years, Kennedy Galvanizing has certainly stood the test of time. This kind of longevity speaks to their ability to provide reliable service and maintain good relationships with those they work for. They have been a consistent provider of hot-dipped galvanizing, a process that is much needed for many different kinds of metal items. Their long run in the industry suggests a steady hand and a commitment to their work, which, in some respects, is very reassuring for customers.

Where Can You Find Kennedy Galvanizing?

Getting to Know Kennedy Galvanizing's Home

The main location for Kennedy Galvanizing is at 301 Industrial Boulevard in Hanceville, Alabama, with the zip code 35077. This is where their corporate office is situated, and it is a key spot for their operations. Hanceville is a community in Alabama, and being located there helps them serve clients in the surrounding areas. It is their primary base of operations, where a lot of the planning and coordination happens, which is pretty central to their work.

Interestingly, the information also mentions another location for Kennedy Galvanizing Inc., at 8256 Stouts Road in Morris, Alabama, zip code 35116. Morris is located in Jefferson County, which is an area that has approximately one county located within the 205 area code. This suggests that while their main corporate hub is in Hanceville, there might be other operational points or connections within the broader Alabama region. It is, like, a bit of a spread in their physical presence, allowing them to reach different parts of the state.

The fact that they are located in Hanceville and incorporated in Alabama reinforces their local roots and commitment to serving their home state. They are listed in various business directories, including the D&B Business Directory, under categories like manufacturing, fabricated metal product manufacturing, and coating activities. This shows their official recognition within the industrial community. So, they are not just a local business, but one with a clear place in the broader manufacturing picture, and that is quite clear.

What Makes Kennedy Galvanizing Different?

Kennedy Galvanizing's Unique Service Approach

One of the standout features of Kennedy Galvanizing is their focus on speed and efficiency. They truly pride themselves on handling "expedited orders" and delivering what they call "extraordinary turn around time" when compared to other galvanizers. For a customer, this means less waiting and quicker project completion. If you need something done fast, they make it a point to try and meet those tight deadlines, which can be a huge benefit for many businesses. It is, like, their way of making sure you get your items back quickly, which is a big deal.

Their commitment to quick service is quite specific. They often offer "same day service" for certain jobs, depending on the size of the order and if they get prior notice before the material is delivered. For other jobs, they typically aim to complete the work within three days. This kind of rapid service is not always common in the industry, and it really sets Kennedy Galvanizing apart. It helps businesses keep their projects moving without long delays, and that is, in some respects, a very valuable thing to offer.

Beyond just speed, Kennedy Galvanizing also places a strong emphasis on the quality of their work. They are committed to providing "quality hot dipped galvanizing at a competitive price." This means they aim to give you a good product without breaking the bank. The quality of their structural material adheres to all ASTM 123 revisions, which are specific standards for hot-dip galvanizing. This adherence to industry standards shows their dedication to doing the job correctly and reliably, which, you know, gives you peace of mind.

Who Helps Make Things Happen at Kennedy Galvanizing?

The People Behind Kennedy Galvanizing

A business is often defined by the people who work there, and Kennedy Galvanizing is no different. The information mentions a superintendent who has been with the company for twelve years. This person played a significant role, running and managing Kennedy Galvanizing Inc. for that period. Their responsibilities stretched from overseeing production to heading up sales and customer relations, which shows a very broad range of involvement in the company's daily workings. It is, like, someone who really knows the business inside and out, which is pretty essential.

The corporate office in Hanceville is stated to have four employees. While this might seem like a small number, it suggests a close-knit team that works together efficiently to manage the company's operations. Each person likely plays a vital role in ensuring that orders are processed, customers are served, and the galvanizing process runs smoothly. It is a focused group, apparently, working to keep things moving along.

The information also makes a brief mention of James Kennedy, noting that there are thirty other people with that name on a platform called AllPeople, and that more info can be found about him and his connection to Kennedy Galvanizing. This might suggest a family connection or a key individual with a similar name who has been involved in the business. The mention of a "Plant Manager / Sales at Kennedy Galvanizing" with relevant experience further points to the dedicated individuals who contribute to the company's success. It is, you know, a team effort, really, that keeps the company going.

A Closer Look at What Kennedy Galvanizing Offers

Understanding Kennedy Galvanizing's Offerings

Beyond the general description of their work, Kennedy Galvanizing provides a hot-dipped galvanizing service that can handle items up to twenty-six feet in length. What is interesting is that they also offer "double dipped" service. This means that for items longer than their initial dipping tank, they can dip one end, then the other, effectively coating very long pieces. This capability allows them to work with a wider range of product sizes, which is quite helpful for customers with diverse needs. It is, like, a way to handle those really long items that might otherwise be a problem for some places.

Their service promise is clear: they provide fast service. This begins with the possibility of "same day service," as mentioned before, which is dependent on the size of the job and if they receive prior notice about the material's delivery. For most other jobs, they aim to complete the work usually within three days. This consistent focus on speed is a key part of their offering, making them a reliable choice for those who need their metal parts protected without lengthy delays. It is a very direct and practical approach to customer service, you know?

The company's commitment extends to providing good quality galvanizing at a price that is competitive in the market. This means they are not just fast, but they also aim to deliver a product that meets expectations for durability and protection, all while being mindful of cost. Their work with structural materials adheres to all ASTM 123 revisions, which are important standards in the industry for hot-dip galvanizing. This adherence shows their dedication to proper procedures and producing a reliable finish. So, they are, in some respects, focused on both speed and a good outcome.

Ensuring Good Work at Kennedy Galvanizing

How Kennedy Galvanizing Keeps Standards High

When it comes to the quality of their work, Kennedy Galvanizing makes sure that their structural material follows all the rules set out in ASTM 123 revisions. These are like a set of guidelines or specifications that ensure the hot-dip galvanizing process is done correctly and that the finished product meets certain performance criteria. By sticking to these standards, they are showing a commitment to providing a consistent and reliable protective coating. It is a way of ensuring that the work they do is up to par, which is pretty important for metal protection, you know?

This adherence to industry standards means that customers can have confidence in the galvanizing they receive. It is not just about dipping metal in zinc; it is about doing it in a way that provides the best possible protection against rust and wear. The process of hot-dip galvanizing itself is a well-established method, and by following recognized revisions, Kennedy Galvanizing is essentially saying that their work is dependable and effective. So, they are, like, making sure that what they do actually works as it should, which is a good thing.

Being a supplier of hot-dip galvanizing, their reputation for quality is quite important. The fact that they have been in business for over twenty-five years and continue to operate suggests that they have consistently met these quality expectations. This long-standing presence in the industry, combined with their stated commitment to quality and competitive pricing, paints a picture of a company that understands the value of good work. It is, in a way, a testament to their ongoing efforts to serve their customers well, which is quite admirable.

Connecting with Kennedy Galvanizing

Reaching Out to Kennedy Galvanizing

If you need to get in touch with Kennedy Galvanizing, their main corporate office is located at 301 Industrial Boulevard, Hanceville, Alabama, 35077, in the United States. This is the central point for inquiries and business dealings. Having a clear physical address makes it easy for people to find them and understand where their operations are based. It is, like, a solid anchor for their business activities.

The information provided also includes details like a phone number and a US DOT number associated with their Hanceville address. These are practical pieces of information for anyone looking to connect with the company for services or business discussions. The phone number allows for direct communication, while the US DOT number might be relevant for logistics or regulatory purposes, depending on the nature of the inquiry. So, they are, in some respects, quite accessible for those who need to reach out.

Kennedy Galvanizing Inc. is also listed with a presence on professional networking sites, showing a follower count of sixty-four or sixty-five users on LinkedIn. This indicates a degree of professional engagement and visibility within their industry. While the corporate office is noted to have four employees, the broader network of people connected to the company, including those with similar names or related experience, suggests a wider reach and influence within the metals and manufacturing community. It is, you know, a way for them to stay connected in the business world.

In short, Kennedy Galvanizing is a long-standing job shop galvanizer that has been operating since March of 1988, offering specialized spin galvanizing and handling structural products up to twenty-nine feet. They are known for their quick turnaround times, often providing same-day or within-three-day service, and they pride themselves on delivering quality hot-dipped galvanizing at a good price. Located primarily in Hanceville, Alabama, with another mentioned location in Morris, they adhere to industry standards like ASTM 123. The company is an Alabama domestic corporation with a history stretching over twenty-five years, supported by a dedicated team, including a superintendent with extensive experience across production, sales, and customer relations. They are, basically, a reliable choice for metal protection.

- Ill Be Your Shotgun Rider Beyonce

- Oreo Mcdonalds Cheeseburger

- Aly Raisman Ass

- Concert Wear Woman

- Kobe Bryant Open Casket

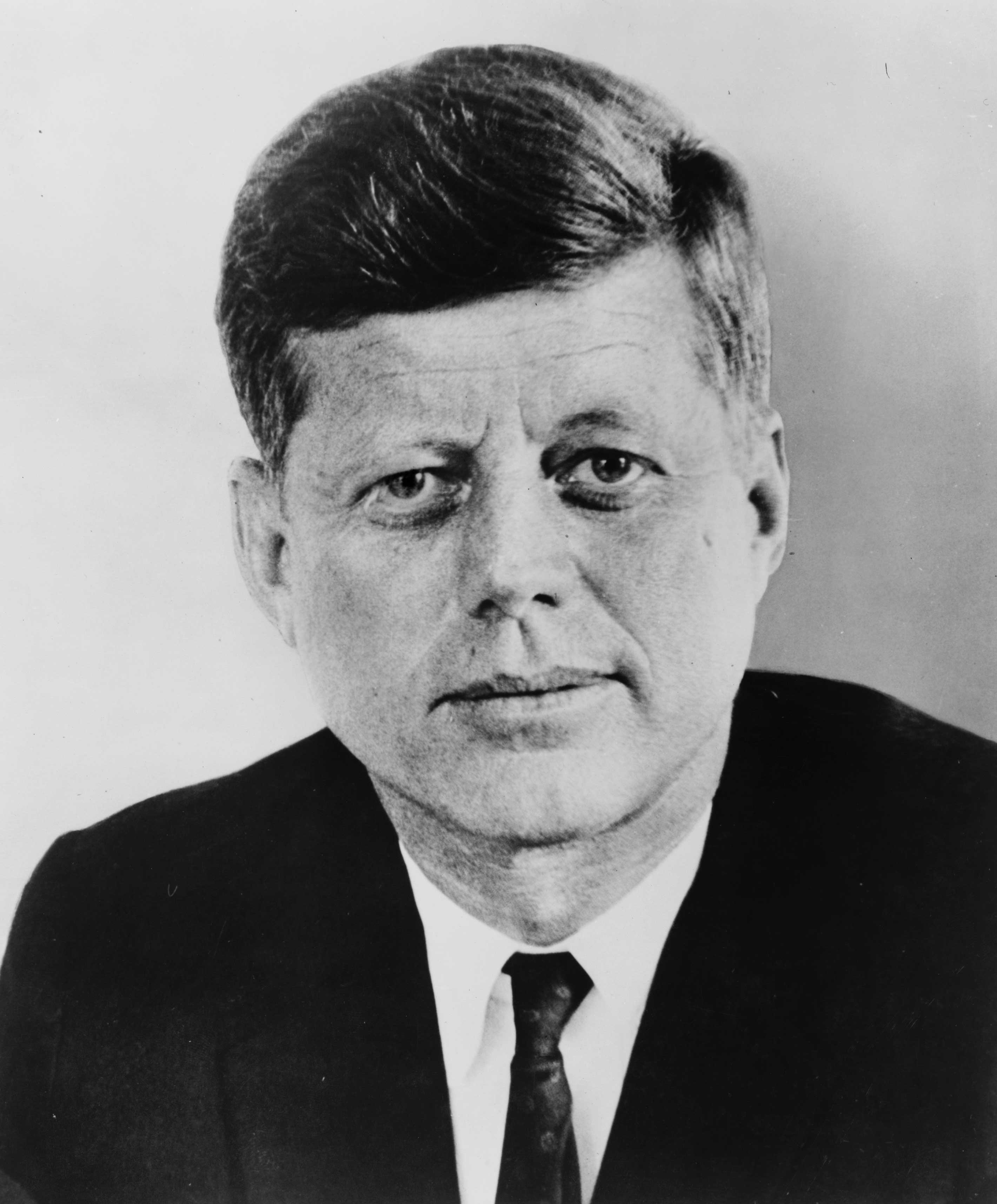

John F. Kennedy | Biography, Family, Presidency, Assassination, & Facts

king-meeting-with-president-kennedy - John F. Kennedy Pictures - John F

Remembering the Assassination of President Kennedy – Marquette